Filler Slabs | Mudkart

Environmental Benefits of Filler Slab Technology

Discover how Filler slabs cut concrete use, lower embodied carbon, improve thermal comfort, and reduce construction waste making buildings greener without compromising performance.

On the day the roof slab was scheduled, the site looked like every other small build: a mixer humming, steel bars tied into a grid, and workers preparing for hours of pouring and vibration. The homeowner walked up the temporary staircase, looked at the reinforcement, and asked the question that almost always comes up now quietly, but with intent: “Is there any way to make this roof more sustainable without taking risks?”

The engineer pointed at the drawing set and smiled. “There is. We’ll use Filler slabs.”

A simple choice can significantly reduce a building’s material footprint. Because concrete is deeply tied to carbon emissions, even a small reduction has outsized environmental values. The cement sector is widely known as a carbon dioxide emitter globally, which is why reducing cement-intensive construction in building homes can be a meaningful sustainable lever.

The Simple Idea Behind Filler Slabs

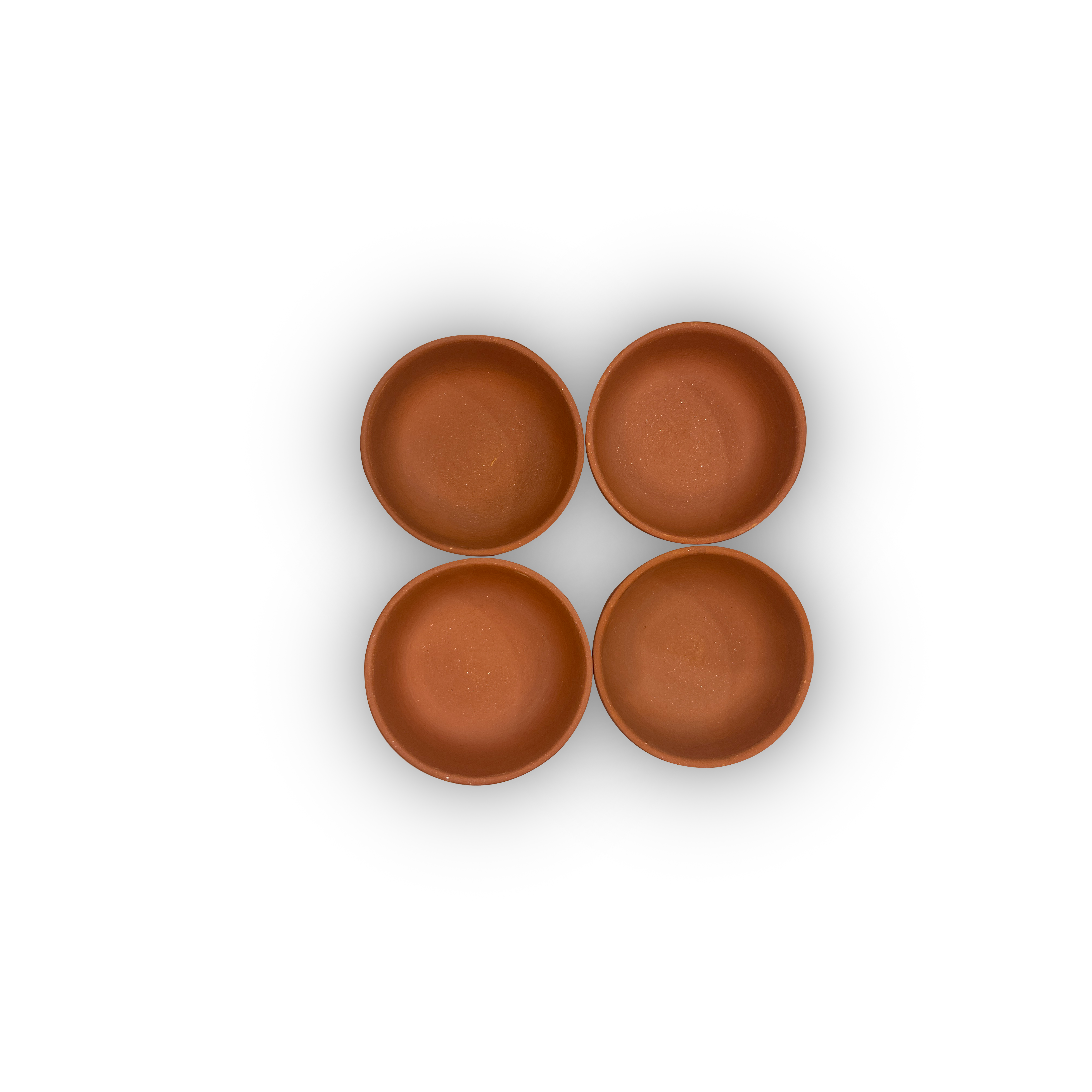

A conventional slab uses concrete throughout, even in the zones where concrete contributes very little to structural strength. In a typical slab, the lower portion experiences tension under bending. Concrete is weak in tension, the reason why steel reinforcement is provided. In a filler slab, the "non-critical” concrete in the tension zone is partially replaced with lightweight filler materials. These are clay pots, terracotta tiles, hollow blocks, or locally available void-formers. They maintain the reinforcement and structural integrity.

In plain terms: you keep what the slab needs for strength, and remove what it does not. That is why Filler slabs are often described as resource-efficient slabs rather than “alternative” slabs.

Environmental Benefits of Filler Slabs

1. Less concrete, lower embodied carbon

You will find concrete everywhere in modern construction. Filler slab construction reduces concrete volume in the slab, also reducing the embodied energy and carbon associated with cement production and material transport. Studies and practitioner references consistently describe measurable concrete savings when filler materials replace the non-structural portion of the slab.

Why does it matter? Because the roof slab can be a significant concrete consumer in low to mid-rise buildings. Reducing the quantity of concrete is one of the most direct ways to reduce the emissions from the project without compromising on the building's function or footprint.

2: Lower dead load, lighter supporting structure

There is another sustainability win that is easy to overlook: weight.

When you reduce the slab’s self-weight, you reduce the dead load carried by beams, columns, and foundations. A lighter superstructure allows rationalized member sizes and reduced material consumption. Less concrete beams, fewer resources in foundations, and sometimes even construction efficiencies in formwork and handling. Research and technical discussions repeatedly say that reduced dead load is also a result of filler slab systems. This is how sustainable design often works in real life, where one decision about material creates a cascade of downstream reductions.

3. Improved thermal comfort, lower cooling demand

Homeowners don't get concerned with the carbon footprint, but they get affected by heat. The top floor of many Indian homes become uncomfortably hot during summers. The solution often defaults to air-conditioning and higher energy bills.

Filler slabs can help in reducing the heat, because many filler materials create air cavities, and trapped air acts as insulation. Many references highlight that filler slab roofs can improve the thermal performance and indoor air quality by reducing heat transfer through the slab.

This shifts sustainability from only “embodied” impact (materials) to “operational” impact (energy). Even small improvements in indoor temperature can reduce dependence on mechanical cooling, especially in hot climates and sun-exposed roofs.

4. Local materials and circularity opportunities

A standard cement or concrete slab is uniform, and supply-chain heavy. They also often take a long time to get transported.

Fillers slabs use locally sourced, lower-impact materials. In many regions, clay pots and tiles are readily available. In some contexts, waste materials can be used as fillers if they are structurally appropriate and are placed correctly. This supports a more circular mindset, which is reducing virgin material use and creating demand for local crafts and small manufacturing ecosystems.

Environmentally, “local” is not just a feel-good label. It can reduce transport emissions, strengthen local supply resilience, and lower the project’s overall resource intensity.

5. Less construction waste and cleaner site practices

Then most visible and effective sustainability is seen in the site itself. Because the filler slabs reduce the quantity of concrete poured, they can reduce spillage, washout, and material wastage associated with over-ordering or over-pouring. The filler units also create a much disciplined “module” for slab formation encouraging planning, and it reduces ad-hoc patch work.

The execution quality varies by site; many practitioners adopt filler slabs precisely because they are a method for doing “less, but better”.

A Quieter, Better Kind of Progress

By late afternoon, the slab was done. What changed wasn’t the building’s ambition, it was the building’s efficiency.

The roof consumed less concrete, carried less dead load, and promised a cooler interior. Sustainability was reinforced with removing what was unnecessary. That is the understated strength of the filler slabs. They make environmental improvement feel practical.

No grand claims just smarter material use, better comfort, and a roof that does more with less.

Talk to us today to know how you can elevate your home with earth-friendly filler slab: Mudkart.